Choosing the right poultry layer cage for egg production chicken farm is crucial for optimizing egg production, ensuring the health of your flock, and managing costs effectively. With a plethora of options available in the market, making the right choice can be daunting. This article will guide you through the process of selecting the most suitable layer cage based on your flock size and budget, ensuring you make an informed decision that benefits both your poultry and your pocket.

Understanding Poultry Layer Cages

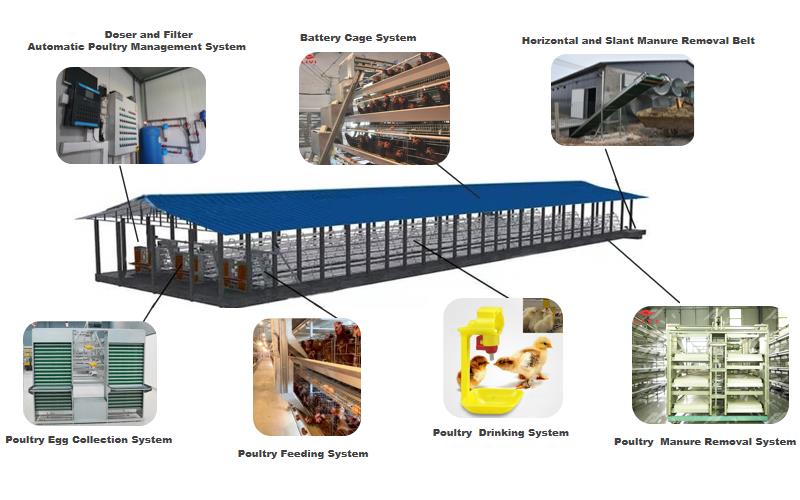

Layer cages are specialized enclosures used for rearing egg-laying chickens. These cages offer numerous advantages, including increased egg production rates, efficient waste management, and reduced disease transmission. Typically, pullets are transferred to layer cages after growing up to 12 or 16 weeks. The design and material of these cages can significantly impact their functionality and longevity.

Factors to Consider When Choosing Layer Cage?

1. Flock Size

Your flock size is the primary determinant of the type of layer cage you should invest in. Here’s a breakdown based on different flock sizes:

- Below 5,000 Birds: For smaller flocks, manual layer cages with automated drinking systems are recommended. These cages require manual feeding, which can be cost-effective for small-scale operations.

- Between 5,000 to 30,000 Birds: At this scale, integrating a manure removal system is advisable. Timely cleaning of chicken droppings reduces disease risks and improves egg production rates, saving time and labor costs.

- Beyond 30,000 Birds: Large-scale operations benefit from fully automatic systems. These include automatic feeding, drinking, manure cleaning, egg collecting, and temperature control. Such systems simplify management, save labor costs, and maximize land use.

2. Budget Considerations

Budget is a critical factor in choosing layer cages. While it might be tempting to opt for cheaper options, it’s essential to consider the long-term implications:

- Material and Durability: Layer cages are available in cold-galvanized and hot-dip galvanized variants. Although hot-dip galvanized cages are pricier, they offer superior durability and resistance to corrosion, making them a better long-term investment.

- Quality vs. Cost: While cheaper cages may reduce initial expenses, poor quality can lead to higher maintenance costs and negatively impact egg production. Always prioritize quality to ensure your investment yields optimal returns.

3. Climate and Environment

The climate in your region can affect the lifespan and functionality of layer cages. For instance, extreme temperatures can impact the durability of certain materials. It’s crucial to choose cages that can withstand local weather conditions to ensure longevity and consistent performance.

Types of Layer Cages

1. Manual Layer Cages

Ideal for small-scale farms, manual layer cages involve manual feeding and egg collection. They are cost-effective and can be upgraded with automatic systems as your farm grows.

2. Semi-Automatic Layer Cages

These cages offer a balance between manual and automatic systems, providing automated drinking and manure removal while requiring manual feeding and egg collection.

3. Fully Automatic Layer Cages

Designed for large-scale operations, fully automatic cages include systems for feeding, drinking, waste management, and egg collection. They reduce labor costs and improve efficiency, making them suitable for farms with over 15,000 birds.

Practical Tips for Choosing Layer Cages

- Consult Experts: Before purchasing, consult with manufacturers or experts to determine the best cage size and type for your specific needs. They can provide insights based on the size of your chicken house and the number of layers.

- Direct Purchase from Manufacturers: Buying directly from manufacturers can save costs by eliminating middlemen. It also ensures quick and efficient customer service if issues arise during the breeding period.

- Design and Layout: Consider the design of your chicken house when selecting cages. The layout will determine the type of cage system you can use, whether battery cages for compact spaces or colony cages for larger areas.

Conclusion

Choosing the right poultry layer cage is a critical decision that impacts your farm’s productivity and profitability. By considering factors such as flock size, budget, climate, and cage types, you can make an informed choice that supports your farm’s growth and efficiency. Whether you’re a small-scale farmer or managing a large poultry operation, investing in quality layer cages will ensure your chickens thrive and your egg production remains optimal. For further guidance, consult with industry experts and explore reputable manufacturers to find the best solutions for your farm.